Electronic instrument trades worker (general)

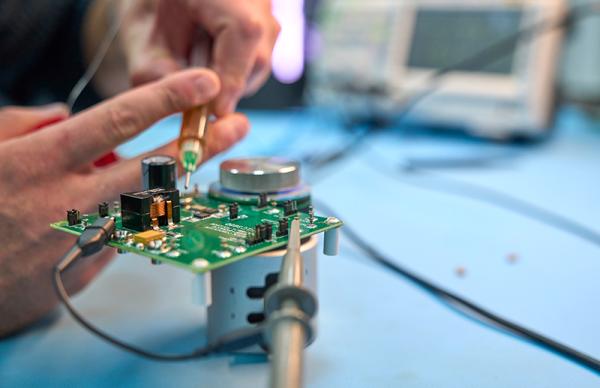

Electronic instrument trades workers examine and test electronic machines, equipment and instruments and control systems. They adjust and repair worn and defective parts of the electronic circuitry and systems, as well as advise users on the correct operating procedures to prevent accidents and malfunctions.

The electronic instruments and control systems measure and control temperature, pressure and flow-in processes used in industries such as petro-chemical, mining, food processing and manufacturing.

Working conditions

Instrumentation tradespersons may work in the minerals and pulp and paper industries, power stations, oil refineries, chemical processing plants and hospitals. Industry is increasingly using instruments in the monitoring and control of various processes.

Tools and technologies

An electronic instrument trades worker may use:

1000V Rated Tools; AC Detectors/Testers; adjustable wrenches; cable cutters; cable tie guns; cable strippers; crimpers; modular plugs; terminals; crimper die sets and frames; diagonal/micro cutters; electrician scissors; ESD extractors, screwdrivers/cutters and ESD static protection; heat shrink guns; hex key sets; IC insertion tools; pick-up tools; pliers; precision screwdrivers; solder aids and tools; workbench magnifiers; wiring installation tools and wire strippers.

Education and training

To become an electronic equipment trades worker you usually need to undertake an apprenticeship in electronics and communications. The apprenticeship usually takes 48 months to complete and is available as a school-based apprenticeship.

Free support and assistance

Your local jobs and Skills Centre can provide free information, support and assistance to help you decide on the best training options to meet your goals.

Disclaimer

The information presented on the occupation profiles within this website is offered as a guide only.